Goodyear Welted Shoes - The Complete Guide

9 min Reading

Most people love shoes. You can find shoes in every shape, color, design, and price. But, is it worth investing in a good pair of quality leather shoes?

According to Harry Jarman, the founder, and editor of The Gentleman's Journal, "Shoes are definitely where you spend your money." It is essential to understand that a good pair of leather shoes will surpass cheaper versions made from synthetic materials.

But choosing good materials is not the only secret of longevity. Shoemakers also use a Goodyear welt construction, making the shoes eternal, comfortable and water resistant.

Table of Content:

- What Are Goodyear Welted or Welt Shoes?

- Who Invented The Goodyear Welt?

- Structure of Goodyear Welted Shoes

- How Are Goodyear Welted Shoes Made?

- Goodyear Welt Patina Shoes And Boots

- MERRIMIUM Goodyear welt Flex

- Benefits of Goodyear Welted Shoes

- How to Identify Goodyear Welted Shoes?

- How To Make Your Goodyear Welted Shoes Last Longer?

- Bottom Line

What Are Goodyear Welted (Welt) Shoes?

Goodyear welted shoes (Goodyear welt shoes) are a type of shoe construction. The construction consists of stitching the upper leather, lining leather, and welt, a unique piece of leather to the ribbing bonded to the insole. Then the welt is sewed to the leather or rubber sole. It's this final stitch that holds the sole in place.

This type of shoe construction is the most durable method making it expensive and time-consuming. It could only be made by highly skilled craftsmanship as it is recognized as an exceptional technique of shoe construction.

Who Invented The Goodyear Welt?

The Goodyear welt was created more than 100 years ago in 1869 by Charles Goodyear Jr, who patented a machine to manufacture shoes with added longevity. His primary purpose was to construct high-quality shoes with the best quality leather.

Charles Goodyear Jr. met a shoemaker named James Hanan, who showed him a sewing machine that made it possible to sew the shoes upper with the insole.

The main difference between this sewing machine and the others is that it doesn't attach the sole with the same stitching.

They both discover that it was possible to make high-quality shoes with a machine's help and not only by hand. Immediately Charles Goodyear Jr patented the machine changing the history of men's shoes.

Since then, the Goodyear welt shoes are considered a sign of wealth worldwide.

Structure of Goodyear Welted Shoes

There are five elements involved in the construction of Goodyear Welted Shoes:

- The Upper - This is the leather above the sole when a shoe is worn. In simple words, it is everything that covers the foot when wearing the shoe.

- The Outsole - Is the material on the bottom and exterior of the sole. It is what comes in contact with the ground.

- The Insole - Is the material inside the shoe that comes in contact with the feet.

- The Welt - On high-quality shoes, the welt is a strip of leather that goes along the outsole's edges. Its main purpose is to attach the upper to the outsole.

- The Last - Is what gives a shoe its structure. It is the three-dimensional model of the foot, and it is used for design and construction.

Now that we know how the Goodyear welted shoes are structured, we can explain how they are made.

It's crucial to understand that there are three basic shoe construction techniques: cementing, blake welting, and Goodyear welting. Without a doubt, the most labor-intensive and most durable is the Goodyear welting.

How Are Goodyear Welted Shoes Made?

Before we discuss how Goodyear welted shoes are made, let's take a quick look at the other shoe construction methods.

1. Cementing

Most shoes use this type of method to attach the sole as it is the cheapest, fastest, and most common. This technique involves tying the sole using an adhesive. Here there is no welting used.

This method's main benefit is that it is cheap and easy to attach the sole, allowing the shoemaker to sell the shoe at a lower price. This method is widely used to attach rubber soles standard in casual and sports shoes.

Unfortunately, with time, the upper begins to separate from the sole. This results in the sole being damaged, and the shoes need to be replaced.

2. Blake Welting

The Blake welting is done inside the shoe, and it is the simplest and most common welting technique.

For this type of shoe construction, the upper is bundled up around the insole and tied between it and the outsole. The main difference with the Goodyear welting is that a single stitch secures everything together.

One of the main problems with Blake's welting is that the shoemaker needs a unique blake machine, making it more challenging and even more expensive than doing a Goodyear welt.

Another problem is that it makes the sole less water-resistant. This method allows the water to locate between the sole and start to pool quicker and easier. Besides, many men complain about irritation in their feet because of interior sewing.

3. Goodyear Welt

This type of shoe construction is the most durable method of the three, and it can be done by machine or hand. The Goodyear Welting is the oldest and most intensive method to construct a shoe as it involves four steps.

Step 1 Preparing the Insole

This method begins with preparing the insole for stitching. For this, the shoemaker needs to create a perpendicular cut that goes around the insole. To generate this rib, the creator can cut and sculpt the insole or use supplementary material.

Step 2 Construct the Shoe

The second step is to construct the shoe; in other words, to last the shoe. The shoemaker does this by stretching the outsole over the shoe structure and attaching it, with the insole to the last.

Step 3 Welt

The third step is to do the welting. Here the shoe cord is sewn over the welt, the upper, and the insole rib using a different stitch; the welt adheres to the outsole. Keep in mind that a latch is used to prevent the chain from separating if it breaks down.

A wooden stalk is added for durability and support. A cork filling is placed between the inner and outsole to give some padding for the feet.

Please note that a machine is usually used to sew mass-produced shoes while unique, high-quality shoes are stitched by hand.

Step 4 Finishing the Shoe

Finally, hot irons are utilized to smooth the sole's edge, proving a hard, round, and polish surface. In this last step, the leather heel is nailed to the sole providing the sole its final trimming.

At this phase, the shoe construction is almost finished, but some final elements are remaining such as:

- The upper and welt are clean and polish.

- The soles are polished with wax

- The shoes are shine and luster

Once the process is done, the shoes are a wrap, box, and send to the retail shops.

The following video shows the process of making a pair of Goodyear Welt in our workshop

Goodyear Welt Patina Shoes And Boots

When combined with the rich tones and meticulously hand-finished patina leather, Goodyear welt shoes achieve an ideal balance of form and function. The patina effect enhances depth and individuality, while the Goodyear welt guarantees long-lasting durability. With proper maintenance, these shoes become a lifetime investment in both style and comfort, growing in character and beauty over time—a true testament to exceptional craftsmanship.

You can read more about Patina shoes in our Blog: Patina shoes - The complete guide

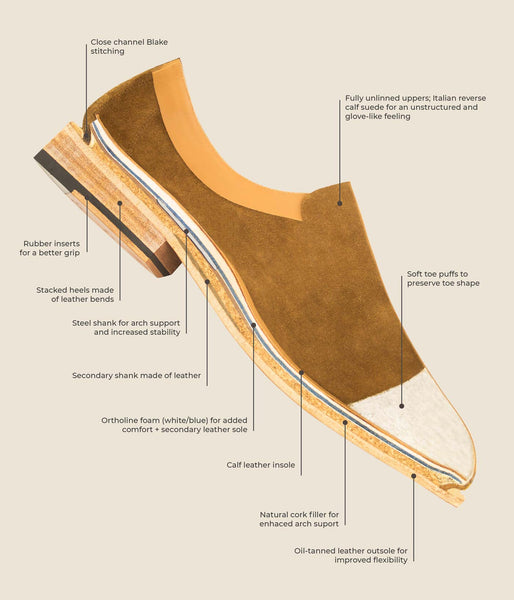

MERRIMIUM Goodyear Welt Flex

The most comfortable shoes ever made!

The Goodyear Flex system is an entirely new production method specifically developed with Comfort in mind while preserving the Quality and Style of the original Goodyear construction. Applying innovative production techniques, we tried to maximize flexibility and maintain durability. The cross section view of one of our shoes indicates how it is made.

These shoes are made from Italian reverse high quality calf suede leather to give a glove like feeling. They are soft, supple, breathable as well as flexible. The sole is made from our revamped oil leather for extra comfort and flexibility. In fact in this raw leather is oil-tanned and stretched before being cut into sole shapes.

Benefits of Goodyear Welted Shoes

Since highly skilled craftspeople do every element of this shoe construction, there are many benefits:

Durability

When you buy Goodyear welted shoes, you know you have made an investment that will last for a long time. Please note that all leather soles let water in but with Goodyear welted shoes, it takes longer for any moisture to penetrate as there is more material between your feet and the ground. Besides, Goodyear welted shoes can be repaired in contrast to rubber soles.

Longevity

It is crucial to take good care of the upper of the Goodyear welted shoes since talented craftspeople can replace the sole and the heel without interfering with the shoe's structure.

One of their main characteristics is that Goodyear welted shoes get better with time. As time passes, the upper takes the shape of the foot, making them more comfortable.

The truth is that Goodyear welted shoes are cheaper in the long run as you don't need to buy a new pair every six months. With proper care, these men's shoes can last between six to ten years.

Comfort

When you buy high-quality men's shoes, you need to understand that there is an adjustment process. The upper must soften and take your foot's shape, the cork filler takes a footprint, and the leather soles need to be scratched up a little to avoid gliding around. After wearing them up to five times, your Goodyear welted shoes will be so comfortable that you won't want to take them off.

Please note that once the shoe is mold to the feet, it provides an almost custom fit.

Goodyear welted shoes can be resoled on many occasions. They also provide superior ventilation and are relatively waterproof.

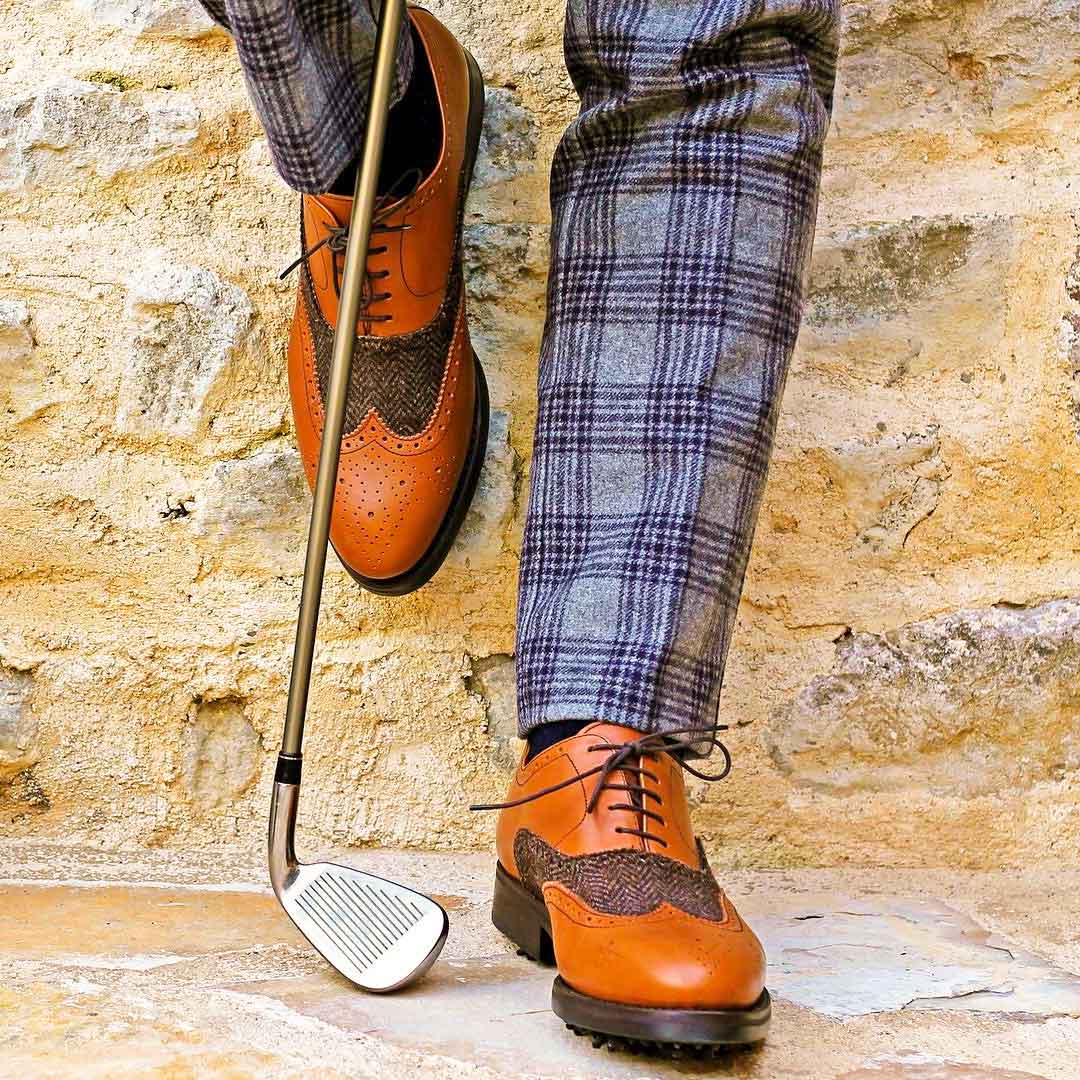

Our handpicked top MERRIMIUM Artist in Italy and Spain produce the best Goodyear welt shoes combined with modern hand painted Patina art. Our limited edition Patina collection offers extra ordinary Patina combined with goodyear welt construction.

How To Tell If a Shoe Is Goodyear Welted?

Goodyear welted shoes have a higher price than those made through other construction methods. Though, they have a longer lifespan and can be resoled on numerous occasions.

Goodyear welted shoes have two stitches. One in the inside of the shoe, as the upper and the border, are sewn together. And two, a welt is sewn to the sole. The welt is a strip of leather that goes around the outside of the shoe.

One of Goodyear's welted shoes' main features is that this construction method does not connect the outside and inside the shoe, providing more water-resistance.

Please note that the space between the outer sole and the insole is filled with cork to provide added insulation and more comfort when wearing the shoe.

It is possible to tell if a shoe is Goodyear welted by noticing the visible stitching on the welt's top and the shoe's bottom.

How To Make Your Goodyear Welted Shoes Last Longer?

A pair of Goodyear welted shoes doesn't need special care, but it is a wise idea to have good maintenance to last a lot longer. Here are some suggestions for proper shoe care.

First Time

It is essential to understand that on first wearing the pores on the sole open. After three or four wears, dirt and dust get impingement into the pores resulting in a protective shield. Make sure to wear the shoes a couple of times in the dry before wearing them in the wet.

Wet Shoes

Please note that if your shoes get soaked, the leather will be fine. If the Goodyear welted shoes get wet, you need to let them dry at room temperature for at least 48 hours. Make sure to place the shoes in a shoe-trees to avoid the leather to adopt odd shapes as they dry.

Allow the sole leather to dry completely since wet soles wear out twice as quickly.

Clean and Polish Regularly

It is crucial to clean the shoes with a dry surface to remove dirt before polishing. Make sure to remove the laces before polishing to prevent them from getting waxy.

We recommend polishing the shoes at night, so you leave it as long as possible. Always use plenty of polish, particularly in the welt and between the upper and sole.

Don't forget to remove excess polish with a cloth or brush. Ultimately, shine the shoes.

Tip: If you want to give tan shoes an old-looking effect, you can use a darker color such as black polish.

Protect The Soles

Goodyear welted shoes can be repaired since we mentioned before, and the sole can be resoled several times. It is an excellent idea to test the sole. Use your thumb to push the spot in the middle of the shoe's front where you walk. When the area feels very soft, it is time to change the sole.

Test the soles regularly to avoid a hole to appear. If a hole appears, it is crucial to stop wearing them immediately to avoid damaging the shoe's insole and structure.

Suede Shoes

If you have suede shoes, always apply a protective spray to shield them from stains or water before and after using the spay, you need to give them a good brush.

Please note it is not necessary to do this every time you wear the shoes. Do it every so often to enhance the resistance.

It is a wise idea to have a suede or nubuck eraser to rub out if you get a small stain or mark. Allow mud to dry before brushing the shoes. If your suede shoes get wet, don't forget to use a shoe-tree or place some newspaper inside and allow them to dry for at least 48 hours.

You can read more in our Blog about how to properly care for your patina shoes including Goodyear welt Patina.

Bottom Line

With proper care, the Goodyear welt shoes will provide your feet with a lifetime of comfort and durability. While they are expensive, wearing Goodyear welt shoes definitely has its advantages. They are one of the highest symbols of quality regarding men's shoes, making it challenging not to appreciate the benefits of wearing the most high-quality footwear worldwide.

Finally, in Goodyear welted construction, the welt is directly stitched to the upper and the sole, but the sole is not directly adhered to the upper. This type of construction has many advantages, including weather-resistant, durability, and comfort.

We, at MERRIMIUM, are producing top quality Goodyear welt shoes by our team of top Artist and Shoemakers in Europe

Leave a comment